Specialized anti-adhesive and hydrophobic films and papers for industry! Release force control, wide range of applications. Check out our offer!

Release films and papers are specialized materials designed to facilitate the easy separation of adhesives, coatings, or composites from the surfaces they are applied to. These products play a crucial role in various manufacturing processes where controlled release is necessary, ensuring that materials do not stick or damage surfaces during processing.

Over twenty years of experience in the coating industry led to the decision to expand Polcoat’s operations. In 2021, we began constructing a coating line, and by 2023, we launched full-scale production of release materials. In the field of silicone coatings, we have complete control over release forces, or the level of non-adhesiveness, of our products. This allows us to meet the diverse needs of various applications and end uses

Sectors

Sectors

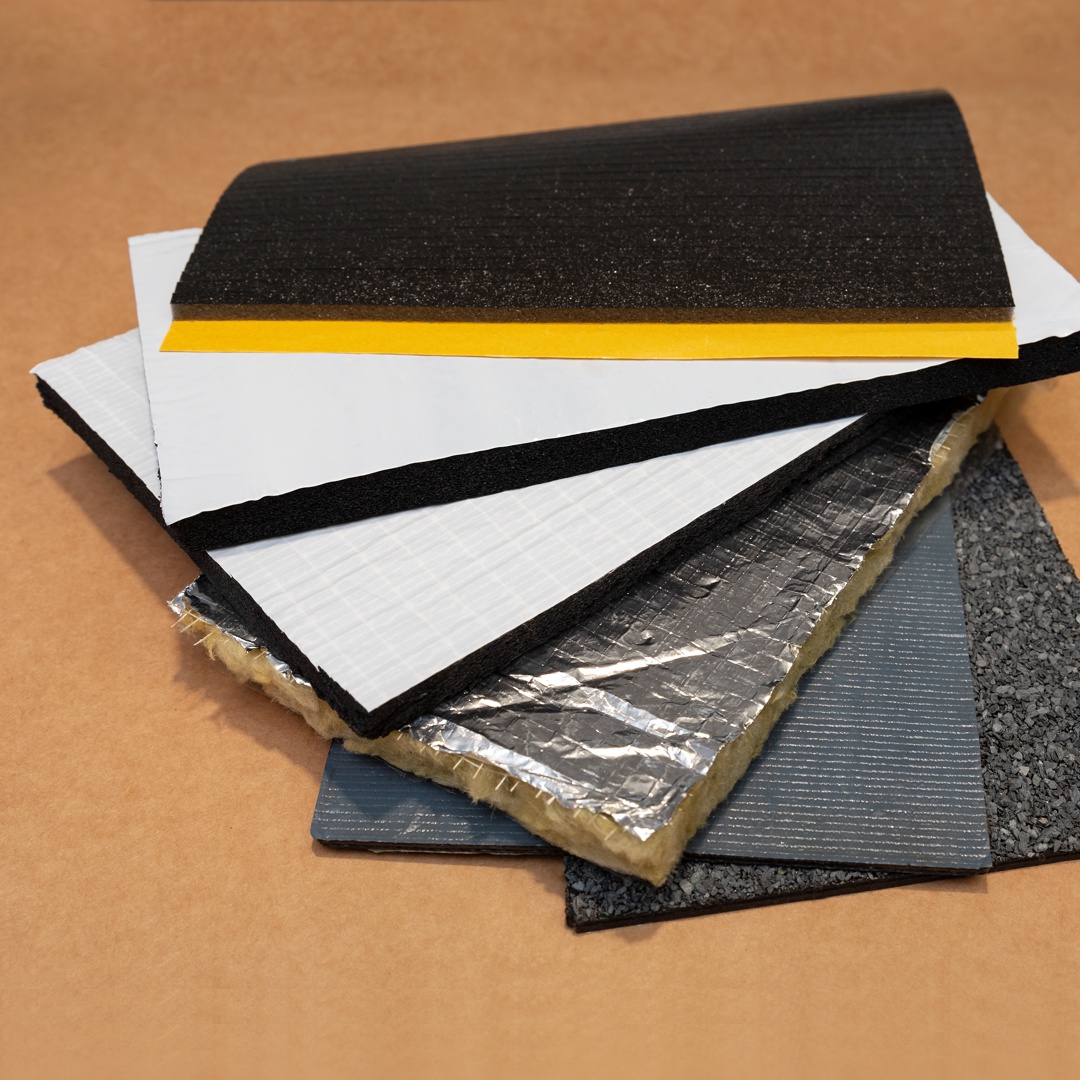

Polcoat release liners are dedicated to various applications. Wide range of one or double side siliconized liners are using in markets:

- Construction

- Building

- Automotive

- Tapes

- Medical

- Label

- Insulation

- Laminated Products

Technical details

Curing method: The technology of cross-linking silicone with UV lamps in a nitrogen atmosphere.

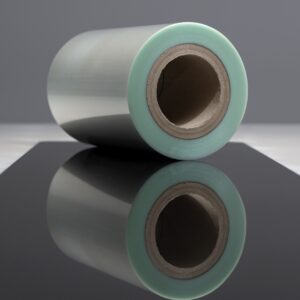

Coating: ONE-SIDE / DOUBLE-SIDE

Release force: super easy, easy, standard, high, customize*

*adapt release force to customers needs

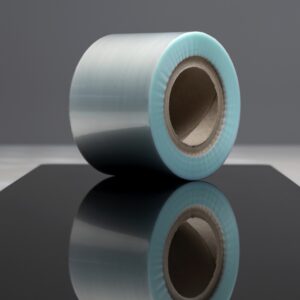

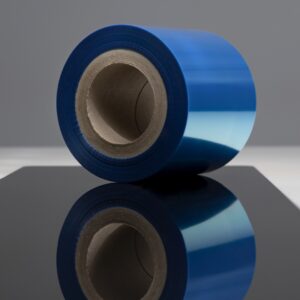

Available films and papers:

Thickness

FILMS 12 – 120μm

PAPERS from 90g

Width: We will precision-cut materials to the specified width, tailoring cutting parameters to each foil, whether you require a wide or narrow ribbon. Range: from 50mm – 1420mm

Additonal features

Siliconization in color

Quality

Tests and release force measure in accordance with the

FINAT standards (FTM1, FTM2, FTM3, FTM9, FTM10)

CUSTOMIZE

Do you use strong, aggressive adhesives? Or is your product supposed to easy peel off? We will adjust the parameters to your application

We aware of the crucial role of precision product we manufacturing. Though chemical processes are invisible, they significantly impact product effectiveness. Our expert team will assist in finding the right release liner for your application.

Main Features:

Main Features:

- Non-stick Surface: Release films and papers are engineered with silicone coating making non-stick surfaces, allowing for clean separation from adhesives, composites, and other materials.

- High Durability: They are made to withstand high temperatures and pressures, ensuring reliable performance in demanding environments.

- Customizability: Available in a variety of thicknesses, coatings, and base materials, they can be tailored to specific application needs.